Concrete Roof Tiles Manufacturing Process

Enjoy the videos and music you love upload original content and share it all with friends family and the world on youtube.

Concrete roof tiles manufacturing process. Flat concrete roof tiles refer to a variety of profiles completely lacking in any barrels or rolls. Each tile is made by sourcing the highest quality raw materials available which are. Our sub six profiles and our flat lightweight 720 lbs. The materials used in their manufacture are sources locally.

Concrete roof tile production. Many homes built with these first concrete roof tiles still remain proving their durability. Concrete roof tile production. It is then discharged into a tile extrusion machine manually or via a conveyor system.

River sand is mixed with a clean finer pit sand to provide the correct sand grading before 42 5mpa portland cement is added and mixed with water. The production process of concrete roof tiles begins with combining four natural products. Sand cement water and iron oxide. Corporate office 3546 n.

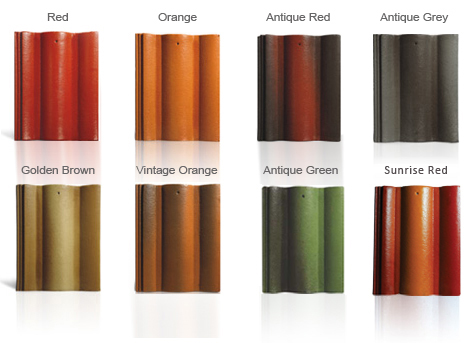

Sand cement water and iron oxide. Rank roofing s concrete roof tile plants ar. Consider beautiful long lasting and economical concrete roofing tiles. Our concrete roof tile portfolio includes beautiful high and medium barrel tile as well as a gorgeous assortment of flat profiles in rich colors and contrasting textures that will complement any residential or commercial architecture.

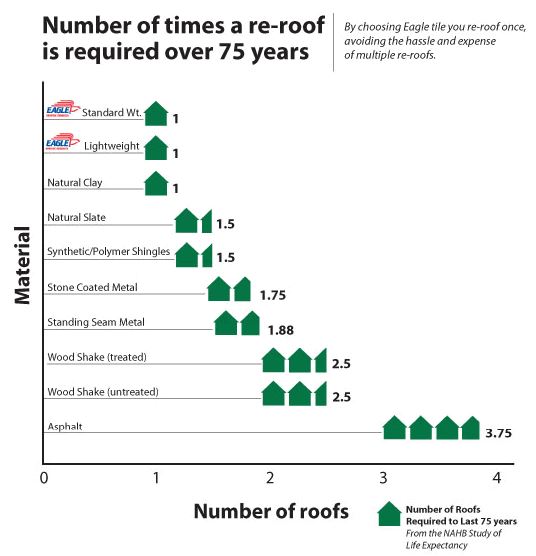

Profiles are a fraction of the weight of our conventional roof tiles and are perfect for re roof projects. The concrete is first produced by a cement mixer. Discover how eagle s superior concrete roof tiles are manufactured at each of eagle s four manufacturing plants concrete roof tiles are rapidly produced at a rate of 1 tile to every 50 to 75 seconds. In the middle of the 19th century in bavaria a mixture of cement sand and water was first used to form roof tiles out of concrete.

Increasingly popular with designers architects and home buyers a flat tile roof offers a crisp clean appearance that perfectly complements both traditional and modern architecture. Concrete roof tiles provide an aesthetically pleasing affordable durable roof for life. The concrete is then extruded onto the top surface of an aluminium pallet that is driven through the machine. The manufacturing process is simple with system from mccathy.