Conventional Sheet Metalworking Operations

Cutting bending and drawing.

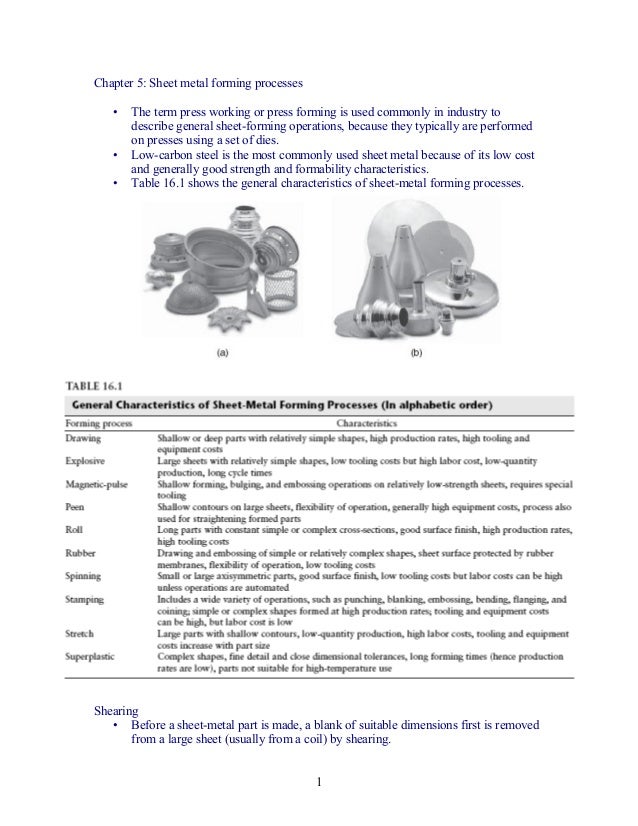

Conventional sheet metalworking operations. All forming operations deform sheet material by exposing it to tension compression or both. The metal being formed must have the ability to stretch and compress within given limits. The first one is sheet metal cutting second one is sheet metal bending or forming and the last one is known as deep drawing in this article we mainly focus on sheet metal cutting operations and other two we will discuss into upcoming articles. In conventional sheet metalworking operations a what is the name of the tooling and b what is the name of the machine tool used in the operations.

Sheet metalworking cutting and forming thin sheets of metal usually performed as cold working sheet metal 0 4 1 64 to 6 mm 1 4in. A punch and die b stamping press. Identify the three basic types of sheet metalworking operations. B the machine tool is called a stamping press.

Conventional spinning also wastes a considerably smaller amount of material than other methods. For additional information visit. Most part defects such as splits and wrinkles occur in forming operations. In conventional sheet metalworking operations a what is the name of the tooling and b what is the name of the machine tool used in the operations.

A the tooling is called a punch and die. In conventional sheet metalworking operations a what is the name of the tooling and b what is the name of the machine tool used in the operations. The standard method of press forming the part. A the tooling is called a punch and die.

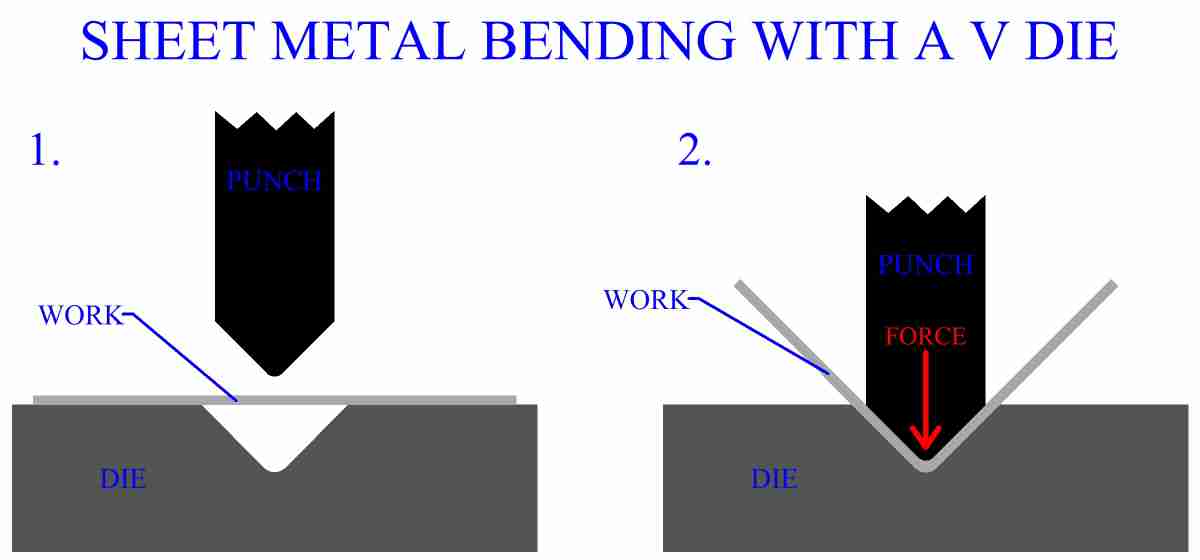

The sheet metal stock is positioned between the punch and die inside the punch press. A identify the three basic types of sheet metalworking operations. The punching process requires a punch press sheet metal stock punch and die. C in blanking of a circular sheet metal part is the clearance applied to the punch diameter or the die.

In conventional sheet metalworking operations a what is the name of the tooling and b what is the name of the machine tool used in the operations. B in conventional sheet metalworking operations a what is the name of the tooling and b what is the name of the machine tool used in the operations. Mainly sheet metal process can be divided into three types. B the machine tool is called a stamping press.

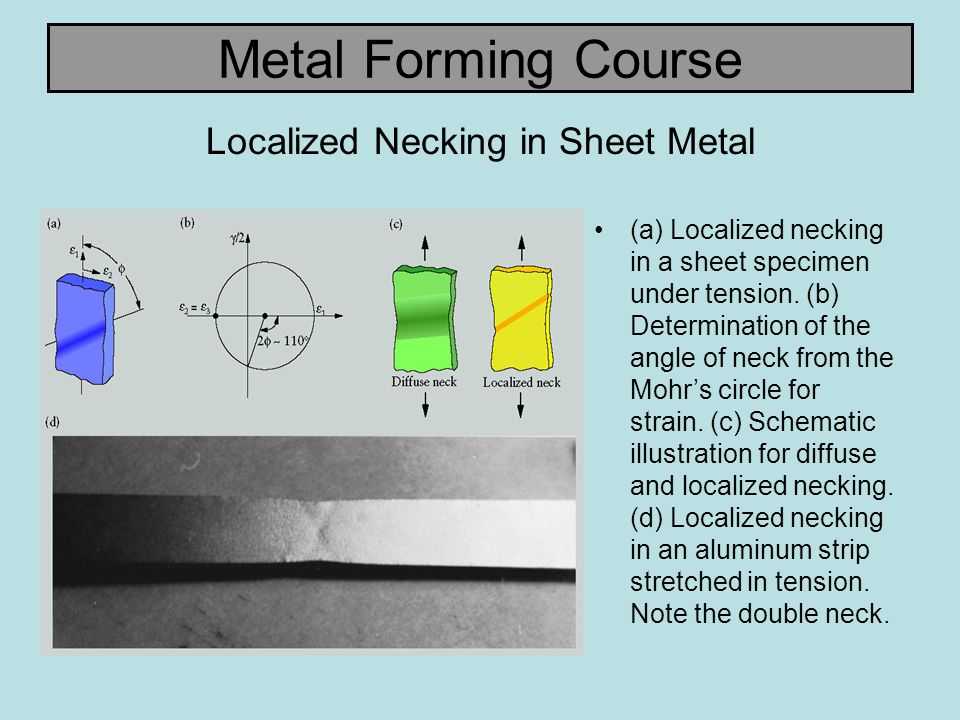

Secondary finishing operations are typically performed to attain smoother edges. Define drawing in the context of sheet metalworking.