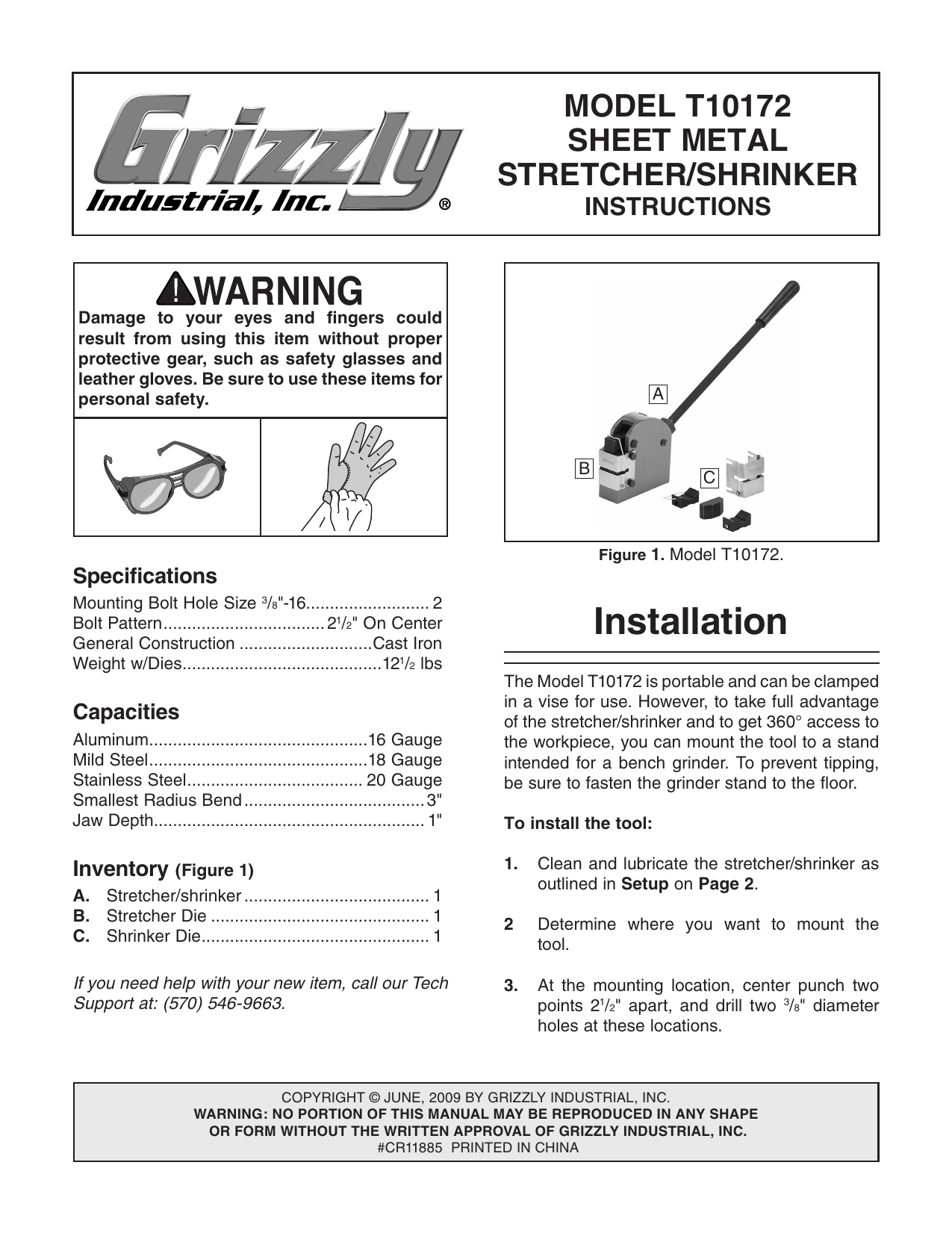

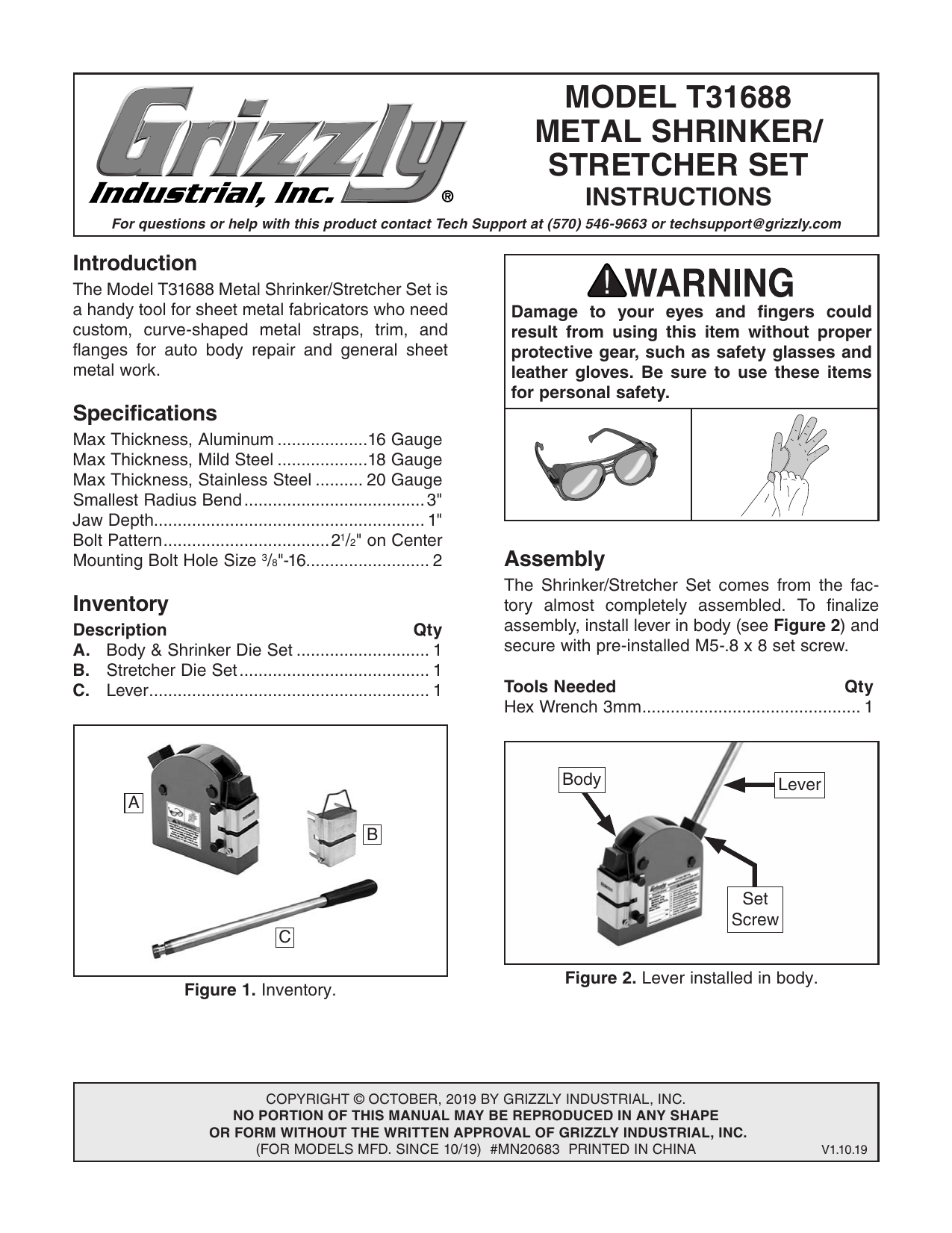

Correct Placement Of Jaw On A Sheet Metal Shrinker Stretcher

When replacing the v blocks shrinker or pressure blocks stretcher chamfered corners face front.

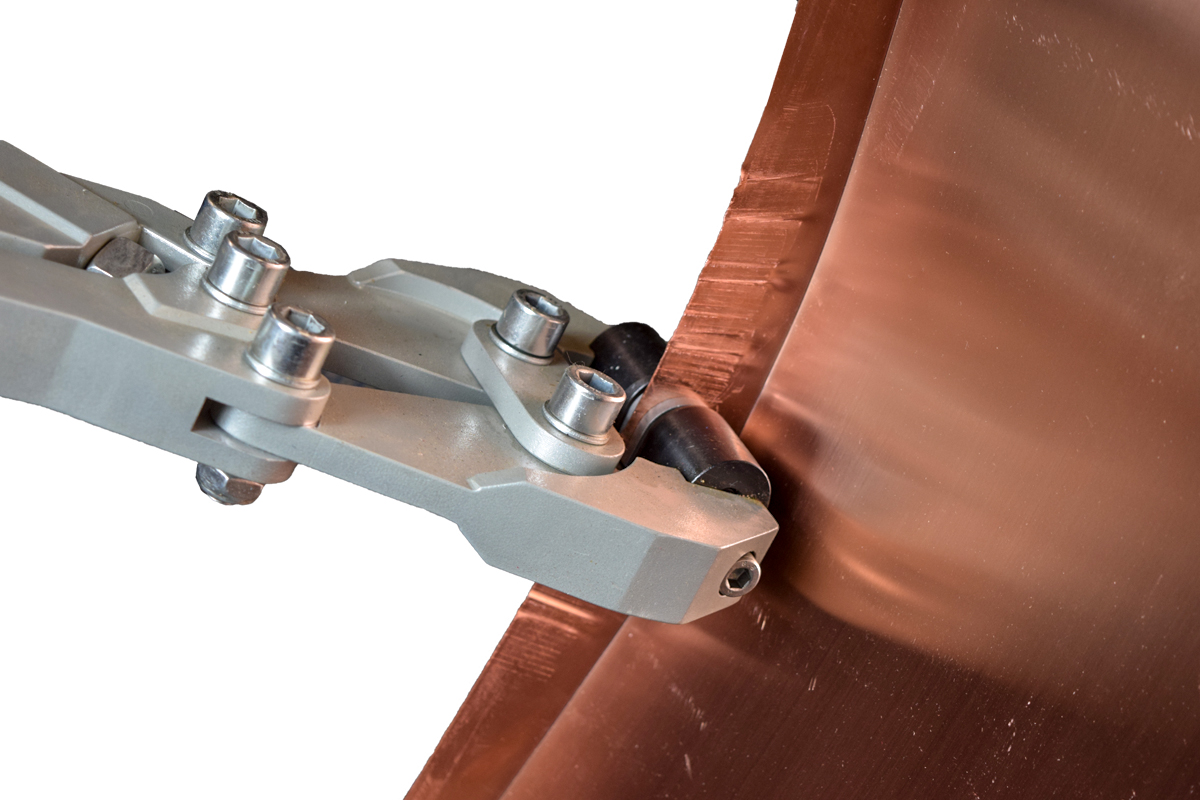

Correct placement of jaw on a sheet metal shrinker stretcher. In this live video matt goes over how to use a shrinker stretcher. Quick change tooling designs our jaw designs help save you time. 11 oil jaws lightly when not in use for extended periods. The shrinker contracts sheet metal for inside curves.

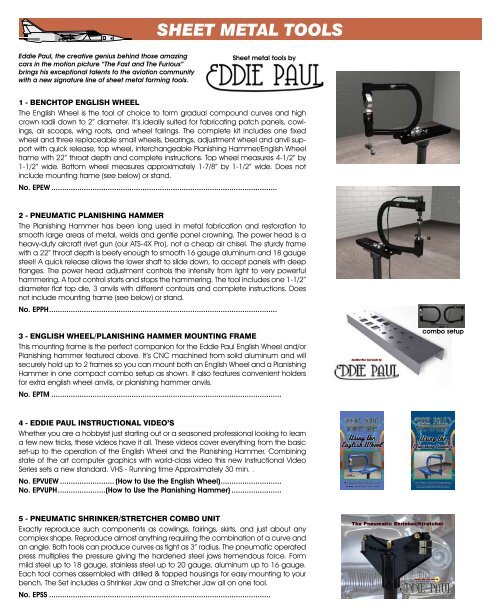

For example it takes seconds to. Clean all as described previously. Reproduce almost anything requiring the combination of a curve and an angle. Models to suit almost any shop our sheet metal stretchers range from an entry level model all the way up to a powerful hydraulic machine.

Why choose metal shrinker stretchers from baileigh. 1 product rating jegs 81708 sheet metal shrinker stretcher 1 in. The tool is typically mounted on a bench or in a vise but you can also attach it to an optional stand with a foot pedal. The elite deep jaw shrinker is for heavy duty or professional use.

The shrinker stretcher can easily be mounted in a vise or on top of a work bench. Save money by making your own windshield channels door jambs wheel openings and more. Up to 3 in. User suffers from less fatigue while putting more shrinking or stretching force to the work piece.

Our standard sheet metal stretcher and shrinker combo set is ideal for most diy workers. Jaw depth blue cast iron inclu. Powder coated to prevent rust. 4 x mounting holes.

The stretcher expands sheet metal for outside curves. Be careful to locate larger shrinker jaw opposite small shrinker jaw. We have a shrinker stretcher to fit your projects. In this video from metal shaping guru lazze he demonstrates the differences between the small shrinker and stretcher and a deep shrinker and stretcher.

Hardened steel jaws have powerful force to curve and angle any 16 gauge aluminum 18 gauge mild steel 20 gauge stainless. The set includes a shrinking jaw and a stretching jaw.